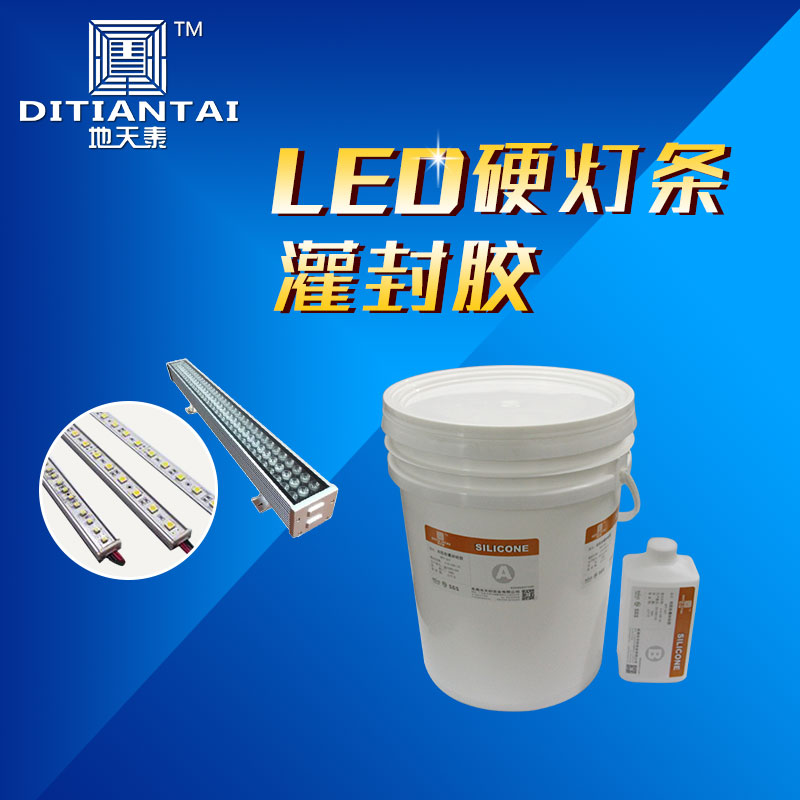

LED Hard Lamp Filling Adhesive

Product characteristics and applications:

DTT312 is a condensated liquid silicone rubber cured at room temperature with two components. It has excellent insulation, moisture-proof and shock-proof performance, which makes electronic components operate safely under harsh conditions. After curing, it is an elastomer with excellent cold and hot alternation resistance and outdoor aging resistance.

DTT313 is mainly used for the sealing of LED hard lamp, line lamp, electrical component, high-voltage component, moisture-proof coating of circuit board, the packaging and insulation of LED indoor and outdoor display board and LED traffic signal lamp in electronic industry.

Main technical parameters:

Projects | Detection standard | Detection result |

Model | / | DTT312 |

Appearance A/B | Visual | Transparent viscous liquid / colorless transparent liquid |

matching | weight ratio | A:B=100:10 |

tack free(25℃)/min | 25oC | 60 |

curing time(25℃)/H | 10 mm thick | 4 |

Full cure time(25℃)/H | 10 mm thick | 24 |

Viscosity/mPa.S | 25oC | 1500±100 |

Density/g/cm3 | GB/T533-2008 | 1.1 |

hardness/ Shore A | GB/T531.1-2008 | 20 |

tear strength/KN.m-1 | GB/T529-2008 | 2.0 |

volume resistivity/Ω.cm | GB/1692-2008 | 1.0*1013 |

operating temperature range | / | -40~200 oC |

Dielectric constant(50Hz) | GB/1693-2007 | 3.0 |

dielectric strength/kV.mm-1 | / | 18 |

Relevant certification | / | ROHS、No halogen, no sulfur |

Note: All the above performance data are obtained at 25, 2 C and 50, 5% relative humidity.

Usage method:

1) Stirring: Before mixing, the A/B component should be shaken 5-7 times in the sealed state, and then used.

2) Mixing: The two components must be completely mixed according to the weight ratio A:B=4:1. Mixing can be done manually or with equipment. If the ratio needs to be changed, the test should be carried out before it can be used in practice. The more B component is used, the shorter the operation time and curing time. The higher the ambient temperature, the shorter the operation time and curing time. Generally, heating is not recommended to avoid pinholes or bubbles on the surface and inside, which will affect the aesthetics and sealing performance of the product.

3) Debubbling: In air-sensitive applications, products need vacuum evacuation after stirring.

4) Working time: At 25 C, the viscosity of the product will increase with the increase of time. When used, it should be ready-made and completed in a short time (30 minutes). Do not pour excessive blended rubber into the remaining rubber container.

Storage, transportation and precautions:

1) The product should be sealed and stored in a cool, dry and ventilated place (5 25 C) to prevent rain and sunlight exposure.

2) At room temperature, the storage period of A gum is 12 months and B gum is 6 months. After long storage, the filler in the gum will settle. Please mix evenly and use it without affecting the performance.

3) This product is a non-dangerous product, but we should pay attention to avoiding the contact between curing agent and skin and eyes. Once contacted, we should immediately clean it with appropriate amount of detergent and water, such as splashing into eyes, washing it with flowing water for at least 15 minutes, and consulting a doctor.

4) After the product is opened, it should be used up as soon as possible. The unused product should be stored in a safe place sealed.

5) This product is non-dangerous and can be stored and transported according to general chemicals.

6) Because of the reaction mechanism, the electrical properties of the product should be tested after 72 hours.

Packing specification:

This product is packed in 8kg/plastic drum and 1L/plastic drum for curing agent.

Warm Tip: Thank you for your trust and support in our company's products. Because of the diversity of practical applications, we can not grasp the application conditions. So users should test before using, in order to meet your requirements and avoid unnecessary waste and loss. Our company does not guarantee any problems arising from the use of our products under specific conditions and does not assume any direct, indirect or accidental liability. If you have any questions, please contact us and we will answer them personally.

Chat

Chat